- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: dongguan

- Brand Name: weibang

- Model Number: 800-2000

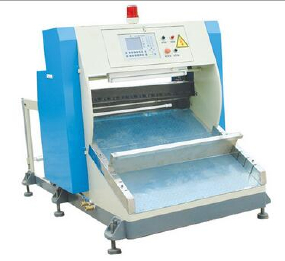

Brand WB model 800-2000 product alias PS foaming machine

The product uses suction plastic electronic industry roller two roller working diameter 350-500 (mm)

The roller line speed of 10-30 (m/min) and maximum distance of 2 (mm) production capacity of 200-350 (kg/h)

Appearance size 3*16*3 (mm) weight 15000 (Kg) motor power 45-75 (kw)

Rolling thickness 0.18 (mm) rolling width 1300 (mm) 24 domestic customer service service within reach

Machining customization is

Company profile

Wei Gang Plastic Machinery Co., Ltd. is a professional R & D, production, sales, service as one of the extrusion complete sets of equipment manufacturing enterprises, has more than and 10 years of history. In continuous digestion and absorption of imported equipment advantages at the same time, the development of more appropriate in the Asia Pacific region plastic production equipment: high productivity, low energy consumption of all kinds of plastic extrusion equipment, to meet the needs of the increasing development of the plastic in the Asia Pacific region.

Specific mechanical types are as follows:

Plastic sheets: (PP/PE/PS/PET/EVA/TPU/ABS/TPR/TSC/PC/MD/PA/PVB, etc.), plate type extrusion line and granulation unit.

CPP/CPE/PEVA/PE film extrusion molding production line;

Multi layer co extrusion (A/B/A type, A/B/C type, foaming / foam, PP synthetic machine group);

PP stationery line machine, electric station, back machine, bronzing machine, bag machine and other organ stationery machinery output;

Slice machine (hydraulic type, high speed type, servo type), friction type automatic winding machine (double / four station, grouping type) and all kinds of auxiliary equipment;

Listed above models can be made according to the special needs of different customers design, the factory has advanced processing equipment and high level professional design talent team, provide a high level of a package of solutions for special manufacturers, turn key service is I plant professional, consistent mode of operation, to provide you with high yield and low cost of production safety equipment, enable us to mechanical quality assurance!

PS sheet molding extrusion unit

Sheet forming process

At present, the production of PP sheet mainly adopts T die, produced by two - or casting method then, the process is as follows:

Ingredients, extrusion plasticization of T type die, pressure light, mucous membrane - forming - traction, trimming - meter long shear product, scrap recycling, crushing

Equipment mainly consists of extruder, swift net changer, a filter, a heater, a cooling water tank, second calender, traction machine, cutting machine and other components, the production line for production 2mm below the PP sheet, with cooling shaping effect is good, high efficiency, less investment and so on.

Two, production line, equipment characteristics

Extrusion machine using well-known brands at home and abroad (Taiwan, Europe and the United States imported), product configuration, low energy consumption, stable performance, wear resistance, high precision;

T type nose using domestic and foreign famous products, quality assurance;

Calender main part: embossing roller can be according to customer requirements in the domestic or imported from Taiwan or customized, so as to ensure the surface sheet of excellent quality;

T type equipment with head wide regulation process, to ensure product quality, at the same time, the loss to a minimum;

In addition to the production line of electrical and mechanical, all the electrical appliances are all imported electrical appliances (motor for the domestic superior product matching), the use of precision and durability of a higher level;

The production line is equipped with the cutting edge device, the computer automatic cutting machine with good performance, which ensures the quality of the product.

PP sheet product standard

The appearance and physical mechanical properties of the sheet are in line with the national ZBG33006-33008-92 industry standard;

When used in food packaging hygiene standards in line with the national GB-85-80 "polypropylene product hygiene standards" and the provisions of the state on the "food plastic products and plastic health management approach," the provisions of;

Stationery sheet has been tested many years ago, all in line with the requirements of Europe and the United States and other countries.

- Place of Origin: dongguan

- Brand Name: weibang

- Model Number: 800-2000